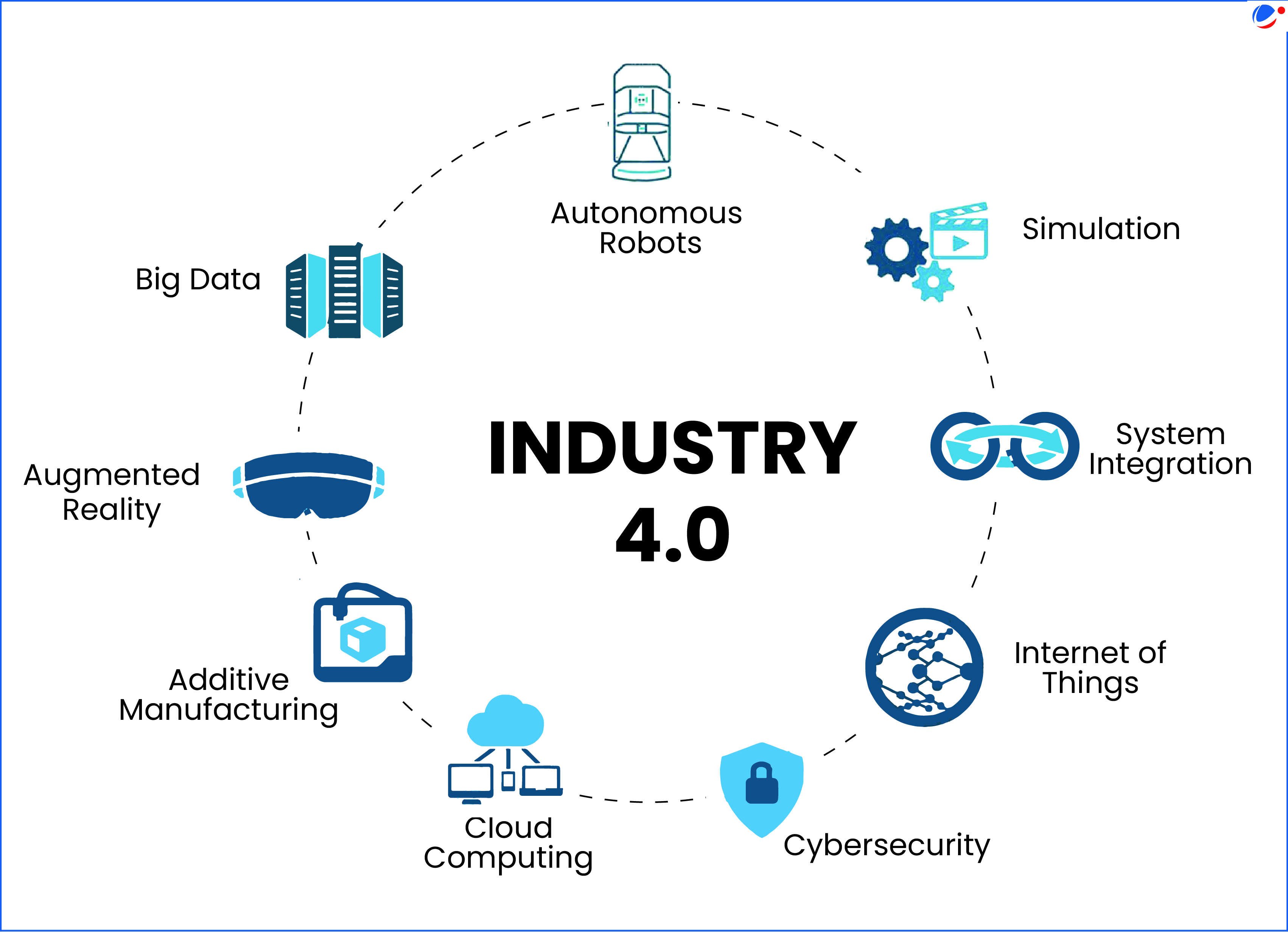

Industry 4.0 refers to “smart” and connected production systems that are designed to sense, predict, and interact with physical world.

Key Highlights of Report

- Industry 4.0 adoption in India: Automotive, electronics, and pharmaceuticals are frontrunners. In contrast, textiles, metals & mining face significant barriers.

- Key Drivers of Industry 4.0 in India

- Workforce Up-skilling, Digital Infrastructure, Sustainability (To meet global consumer and regulatory expectations for green manufacturing).

- Barriers to Adoption

- Awareness: Many MSMEs lack understanding of Industry 4.0's benefits versus costs.

- Technological Barriers:

- Legacy Systems: Difficult to integrate with modern tech.

- Data Integration: Challenges in handling big data across systems.

- Cyber-security Risks: Increased digital exposure brings higher risks.

- Financial Constraints: High initial investment and ongoing costs, limited access to funding.

- Human Resource Issues: Shortage of skilled workers and cultural resistance to new methods.

- Way forward:

- Harnessing Global Value Chains (GVCs) present immense opportunities for MSMEs to access global markets and enhance competitiveness.

- Develop comprehensive digital strategies and phased implementation roadmaps.

- Other focus areas: Prioritize key technologies such as AI and automation, invest in workforce up-skilling etc.

Government Support and Policy Interventions

|