Why in the News?

It has been 5 years since the launch of the National Technical Textiles Mission.

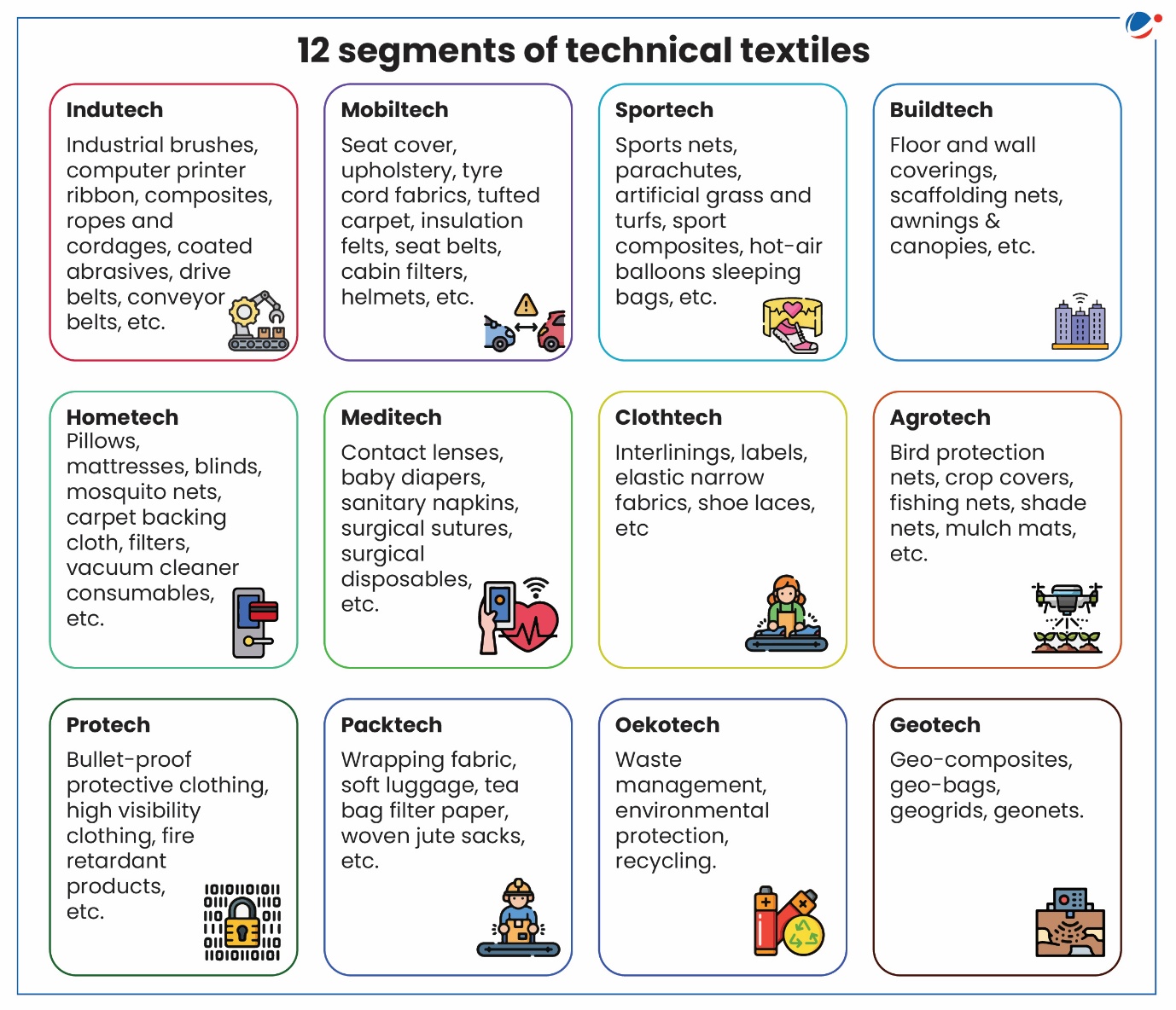

Technical textiles are fabrics made for specific functions and performance, rather than for looks.

|

About National Technical Textiles Mission

- Aim: To make India a global leader in Technical Textiles with a budget of Rs. 1,480 crores till 2025-26.

- Ministry: Ministry of Textiles.

- Four Components:

- Research, Innovation and Development.

- Promotion and Market Development.

- Export Promotion.

- Education, Training, and Skill Development.

- Objectives of NTTM: It aims to strengthen India's position as global leader in national textiles by developing an ecosystem around it.

Why Technical Textiles are significant for India?

- Diversified Applications: Indian Technical Textile market is equipped with diversified technical textile innovations.

- For instance, hometech has been used for Antiviral Mattress Protector.

- Agrotech has been used for UV Stabilised and Flexible Crop Support Net.

- Increasing Demand: More consumers have now started to prefer technical textiles over traditional textiles as it fulfils their demand for flexible, durable, high-quality and high strength textiles in activewear or medical apparel.

- Similarly increasing population, rising birth rates and aging population continues to boost the demand for hygienic and personal care medical equipment (meditech), as well as buildtech segments.

- Industrial Production: Indutech are technical textiles used in the industrial (manufacturing) applications like filtration, conveying, cleaning including solutions and products for mechanical engineering and for varieties of industries, e.g. conductive textiles and 3-D textile products.

- Environmental Protection: Technical Textiles, especially Geotech and Oekotech are useful for environment protection – floor sealing, air cleaning, prevention of water pollution, wastewater recycling treatment, erosion protection and domestic water sewerage plants.

- Supports Disaster Management: For instance, in Austria, Geotech barriers used to deflect avalanches from entering the reservoir.

- Defense Modernization: Manufacturing of Protech based bullet proof jackets, protective wear, high strength composite materials under make in India can help in defense modernization.

- Support for Key Sectors: Technical textiles enhance productivity and efficiency in critical sectors like agriculture, healthcare, transportation, and infrastructure, which are foundational to India's economy.

- Geotextiles in railway track construction (e.g., by Indian Railways under NIP) and geomembranes for water conservation (Jal Jeevan Mission) improve infrastructure durability, reducing maintenance costs and supporting long-term economic stability.

Other Steps taken to Promote Technical Textiles

|

Challenges in Leveraging Technical Textiles

- Lack of Awareness: Technical textile benefits remain unknown to the masses due to insufficient marketing and education.

- Import Dependence: India imports significant technical textiles from China (low-cost products) and US/Europe (high-tech products).

- The absence of domestic specialty fiber manufacturing (carbon fibers, Nylon 66, UHMPE) and inverted duty structures favor importing finished goods over raw materials.

- Skilled Workforce Shortage: The industry requires specialized skills currently absent in the domestic workforce.

- Current training schemes focus on traditional textiles rather than developing specific technical textile curricula.

- Insufficient R&D: The industry is dominated by commodity products with limited product diversification.

- Despite government-established Centers of Excellence, industry mindset needs to shift toward innovation and research investment.

- Standardization Issues: Harmonization of Technical Textiles HSN codes and alignment with international standards remains a challenge, complicating trade and quality control.

Way forward

- Strengthen Research and Development (R&D): Prioritize R&D in high-growth segments like Geotech, Meditech, and Agrotech by collaborating with the premiere institutes so as to support cutting edge innovation.

- Increase Export Competitiveness: By harmonizing Indian standards with global norms to enhance product acceptance in international markets.

- Focus on Sustainability and Circular Economy: Promote the use of natural fibers and eco-friendly products like Agrotech nets and Geotech erosion control solutions to align with India's vision of Mission LiFE.

- Leverage Global Best Practices: Adopt advanced manufacturing techniques from leaders like the USA (Sportech innovations) and Germany (Geotech applications) or Israel (Protech innovation) to improve technology readiness levels.