Why in the news?

Recently, NITI Aayog's Frontier Technology Hub, in collaboration with the Confederation of Indian Industry (CII) and Deloitte, unveiled a 10-year roadmap titled "Reimagining Manufacturing: India's Roadmap to Global Leadership in Advanced Manufacturing".

Key Highlights of the Roadmap

- Core Frontier Technology Enablers: Artificial Intelligence & Machine Learning, Advanced Materials, Digital Twins (virtual, data-driven replicas of physical systems), and Robotics.

- Key features of the roadmap

- Sector-Focused Approach: It identifies 13 priority manufacturing sectors where frontier technologies can generate the greatest impact, ranging from electronics, semiconductors, and pharmaceuticals to green energy.

- Frontier Technology Integration:

- Artificial Intelligence & Machine Learning for predictive maintenance, quality control, and process optimization.

- Digital Twins to simulate real-time factory environments.

- Advanced Materials to enhance product performance and sustainability.

- Robotics and Automation to improve precision, productivity, and safety.

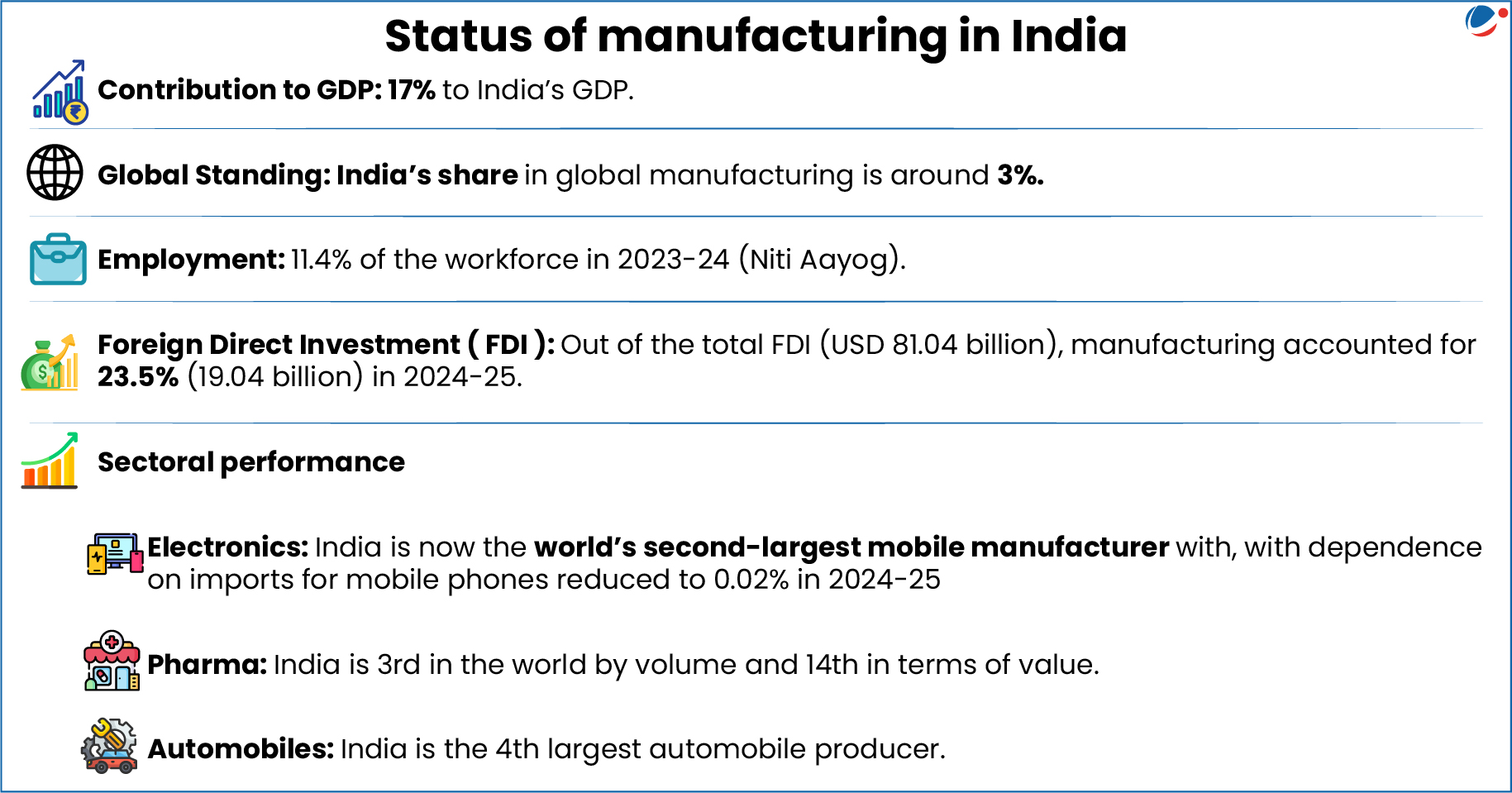

Significance of Manufacturing

- Balancing Economic Structure: Manufacturing shifts labour from low-productivity agriculture to higher-productivity non-farm employment, which the service sector could not achieve desirable scale.

- Employment: The sector has the highest backward and forward linkages compared to any other sector, i.e., it generates more jobs indirectly for every direct job created.

- Strategic autonomy: A strong manufacturing base enhances self-reliance in critical sectors such as defence, semiconductors, pharmaceuticals, and energy equipment.

- COVID-19 exposed dependence on imports for APIs, medical equipment, and semiconductors.

- Innovation spillovers: Manufacturing fosters R&D spillovers, supplier development, skilling, and ecosystem-wide productivity gains.

- Regional Balance: Manufacturing can decentralise growth by creating jobs in Tier-2, Tier-3 cities and rural hinterlands, reducing distress migration to metros.

- E.g., Micro & Small Enterprises Cluster Development Programme, a central sector scheme focusing on rural areas, the northeast, aspirational district for balanced regional development.

Challenges Faced by Manufacturing in India

- Funding Gaps: By the government and industry for frontier technologies to support pilot-to-scale transitions.

- Inadequate adoption of these technologies could result in a reduction of India's share of global manufacturing to 2.5% by 2035 (NITI Aayog).

- Low Investment in R&D: E.g., R&D spending in India accounted for only 0.64% of GDP in 2023, far below China, which spent around 2.5%.

- Disincentives to Scale: Stringent regulations incentivise MSMEs to remain small to avoid regulations and taxes, reducing employability and scalability.

- Approx 35.5% of manufacturing output is accounted by MSMEs.

- Manufacturing vs Services Imbalance: India experienced services-led growth; bypassing manufacturing-led structural transformation seen in East Asia, e.g. Services account for approximately 55% of GDP.

- This has resulted in unemployment as Services (especially IT and finance) are high-productivity but low-employment sectors.

- Low labour productivity: According to the ILO, GDP per working hour in India was $8, placing it at the 133rd position.

- Unequal distribution: The top 5 states account for nearly 54% of manufacturing GVA.

Initiatives by Government for boosting Manufacturing

|

Conclusion

To unlock the full potential of the manufacturing sector, India may pursue coordinated reforms in regulations, land, tariffs, infrastructure, and logistics to reduce costs and improve ease of doing business. Simultaneously, greater investment in R&D, adoption of frontier technologies, and industry-aligned skill development are essential.